Introduction of examples of maintenance and conservation practices

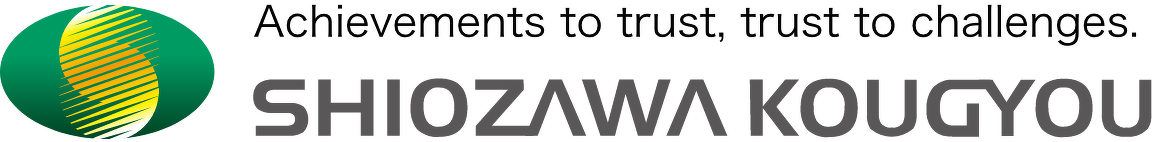

Case studies of periodic inspections of tapping centers.

This case is a tapping center that forms a line for processing parts, and the machine is in full operation for processing mass-produced goods. For such equipment, a sudden breakdown of the machine due to failure would cause significant damage to the company. In addition, if replacement parts are needed, the downtime period may be even longer depending on the delivery date of those parts.

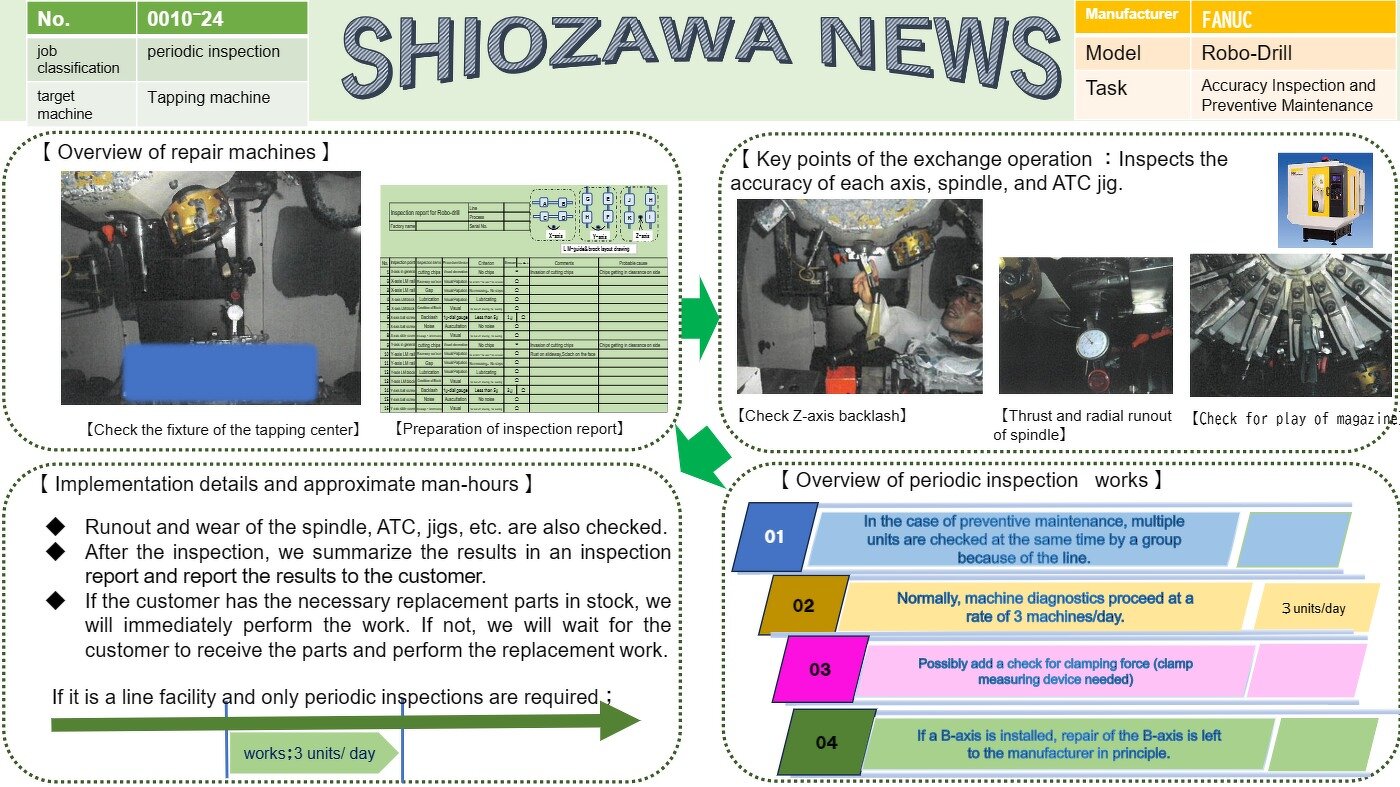

Planning preventive maintenance, such as conducting periodic inspections of production equipment, is essential to ensure stable operation of the equipment and consistent quality of the processed workpieces.

Periodic inspections enable the early detection of consumable parts, etc., and timely provision of necessary parts.

Shiozawa Kougyou provides periodic maintenance services based on discussions with customers.