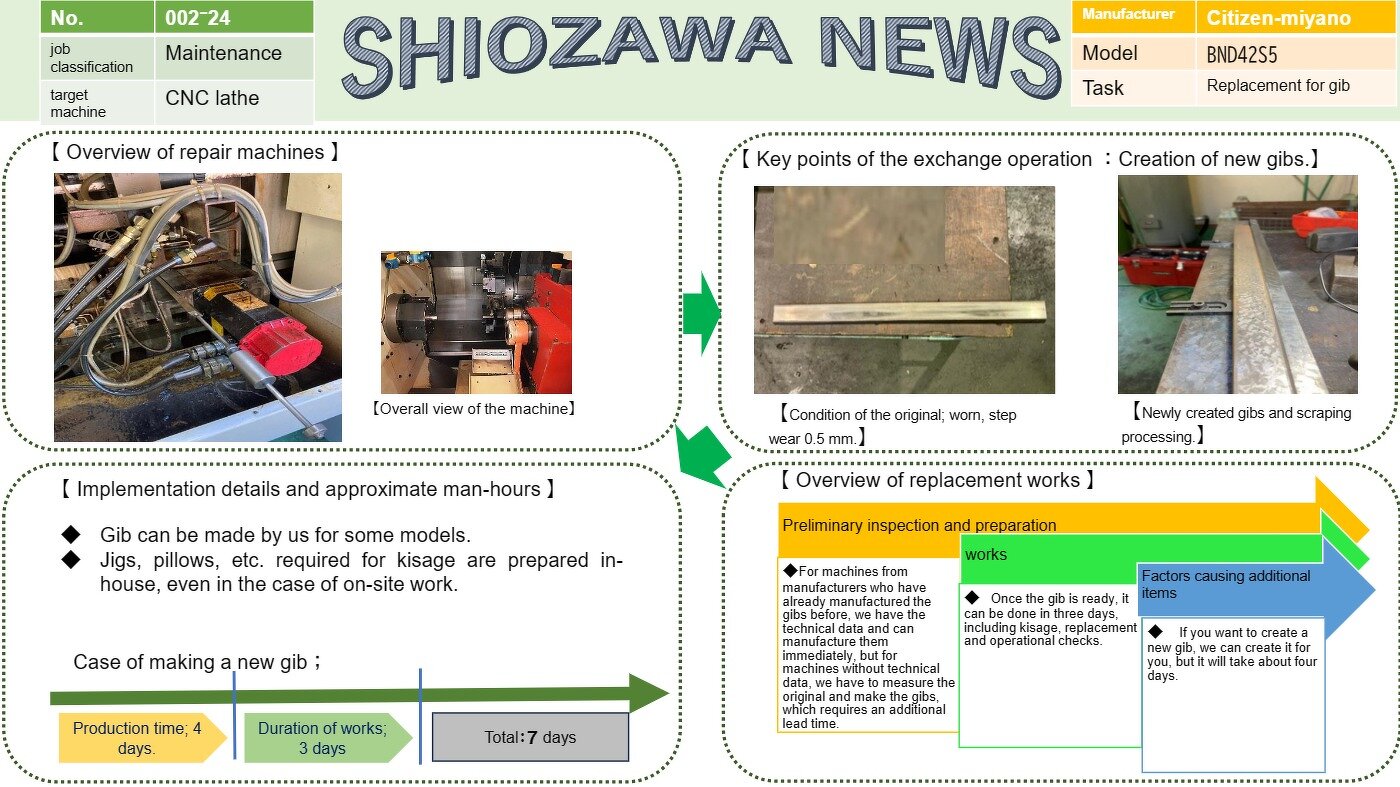

Introduction of examples of maintenance and conservation practices

Case Study of Gib Replacement Work

Introduction of actual cases of Gib replacement on NC lathes;

Many machines such as lathes, machining centers, and grinders use Gib in their operating parts. Gibs are usually designed to be slightly adjustable, but due to wear caused by long-term operation, they become worn to the point where adjustment is no longer possible.

In this case, even if the ball screw and tac bearing are replaced, the accuracy will not be stable and the life of these replaced parts will be shortened, resulting in frequent inaccuracies. In this case, the Gib will need to be replaced.