We can consistently deliver high accuracy.

We have expertise in machine tools and industrial machinery.

Assembly (OEM / Assembly Support)

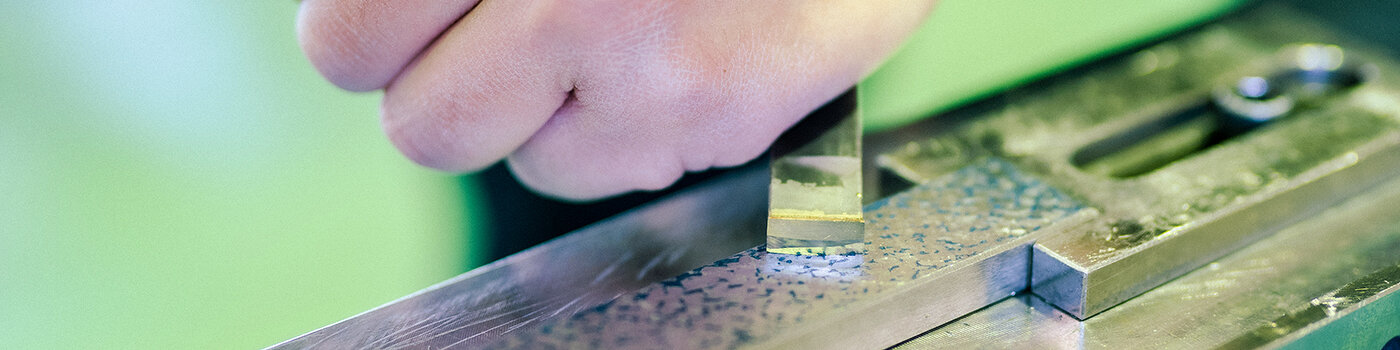

In order to achieve high precision in machine tools and industrial machinery, it is important to ensure that assembly is performed properly.

This is because the accuracy of the machine will vary greatly depending on the type of technology applied during the assembly process.

In order to achieve a high level of accuracy, "technique to achieve target accuracy" and "strict quality inspection" are indispensable.

As for the technique to achieve target accuracy, our skilled engineers align the straightness and flatness of the unit in 1 micron increments through "Kisage (scraping) processing" and apply "correct alignment technique in assembling process" to match the height of the cutting tool and the center of main spindle. In the quality inspection, the test trials are conducted to strictly verify motions, performance and accuracy. The entire assembly is adjusted while ensuring that all assembly accuracy is in line with the design.

The high level of assembly technique that we have achieved is backed up by our extensive experiences trained in a variety of fields, including OEM production in-house, as well as secondment to major machine tools and automobile manufacturers.

Overhaul

We can repair the latest machine tools and industrial machinery, as well as overhaul old model machine tools that other companies cannot handle. Old machines that cannot be operated due to mechanical or electrical problems can be restored to near-new condition. We can handle old machines that do not have drawings, or for which parts are no longer supplied due to the withdrawal of the manufacturer or the end of production. Our engineers, who have handled machine tools and industrial machinery of numerous manufacturers in Japan, will overhaul your machine with their highly skilled technique. Worn and aged parts are restored to like-new condition through in-house machining, etc. We even maximize accuracy of machining by kissage processing etc., so you can use your machines with peace of mind after the overhaul.

Maintenance (Production Preparation Support)

Maintenance is essential for stable operation of production lines.

If maintenance is performed only after a breakdown has occurred, repairs may be delayed due to missing parts, etc., and it may take a long time before the line is restored. Sudden line stoppages due to trouble or breakdowns can also directly lead to a drop in sales.

In order to prevent such a situation, we proactively propose periodic preventive maintenance. Preventive maintenance involves checking machine parts and replacing them on a regular basis. Regular checks not only reduce the occurrence of defective products and maintain stable quality, but also prevent unforeseen situations such as long stoppages of production lines due to waiting for parts to arrive. We have experience in maintenance at the plants of many major automobile manufacturers and other plants in Japan and overseas.

Machining

We are capable of single-part machining and restoration of hard-to-find old machine tools and industrial machinery parts using our own equipment. We are constantly machining parts for overhauls and parts requested by major machine tool manufacturers using general-purpose lathes, NC lathes, general-purpose milling machines, NC milling machines, machining centers, and other machining equipment. Further, we have the technique to meet even the highest form accuracy, therefore, your company can rest assured. We will gladly accept difficult orders that other companies have refused, such as short lead times, high-mix low-volume production, and prototype production.

Glossary of Technical Terms

A glossary of technical terms for manufacturing engineers, including technical explanations of the manufacturing industry.